In today¨s era of rapid technological advancement, smart manufacturing has become a key direction for industrial transformation and upgrading. As an essential component of smart manufacturing, sensor technology plays a critical role and is regarded as the ^cornerstone of smart manufacturing. ̄ This article will delve into the significance of sensor technology and analyze its specific applications and roles within smart manufacturing.Even if there are obstacles to moving forward, Fiber Optic Sensor We should also persevere, forge ahead bravely, cut waves in the sea of the market, hang on to Yun Fan and strive for the first place. https://www.hfyakexi.com/

The Close Relationship Between Smart Manufacturing and Sensor Technology

Smart manufacturing is a new production method that integrates knowledge engineering, manufacturing software systems, robotic vision, and robotic control to model the skills of technicians and expert knowledge, allowing intelligent machines to conduct small-batch production without human intervention. The development of this concept marks a new intelligent era in industrial manufacturing. Sensor technology, as a pillar of information technology, is a critical technology indispensable for realizing smart manufacturing.

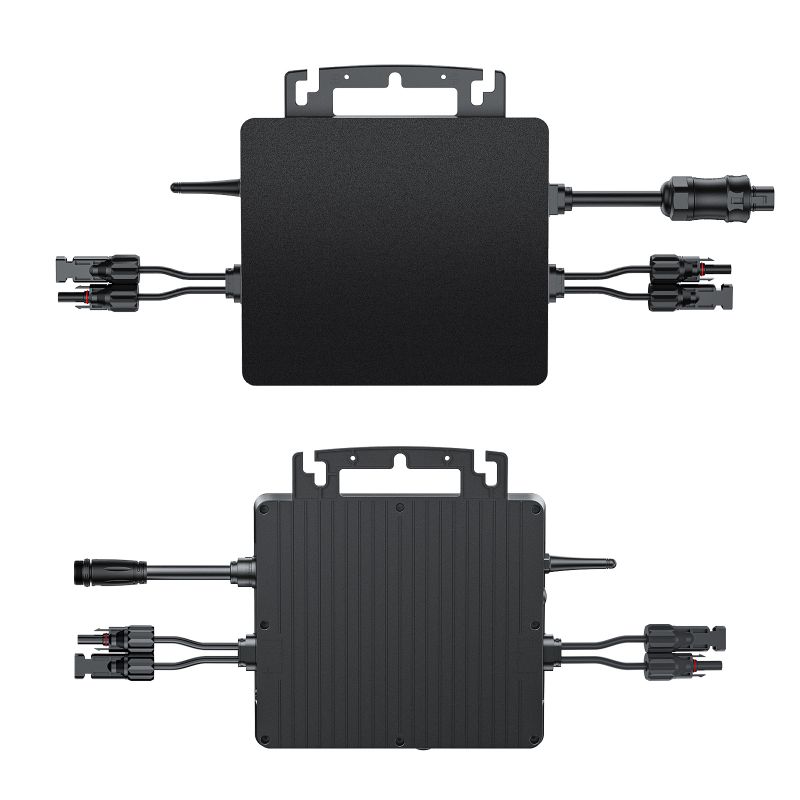

A sensor is a device or apparatus that can sense a specified measured quantity and convert it into a usable output signal according to certain rules. These measured quantities can be physical, chemical, or biological, and the output signals are usually electrical. Sensors use physical, chemical, or biological effects to convert detected information into electrical signals, laying the foundation for information acquisition, transmission, and processing.

Applications of Sensor Technology in Smart Manufacturing

Data Collection and Monitoring

Sensor technology is the core of data collection and monitoring in the smart manufacturing process. By installing various sensors on production equipment, processes, and products, critical parameters such as temperature, pressure, displacement, and speed in the production process can be collected in real-time, allowing precise monitoring of the production process. This data provides a basis for production management and decision-making, as well as a foundation for subsequent data analysis and optimization.

Fault Diagnosis and Prediction

Intelligent sensors not only have data collection capabilities but also possess logical judgment and data processing capabilities. Through built-in algorithms and models, sensors can analyze and calculate the collected data, enabling timely diagnosis and prediction of equipment faults. For instance, in the manufacturing industry, engine performance evaluation, fault diagnosis, and life prediction systems based on smart sensing technology can monitor engine operating conditions in real-time, detect potential faults in advance, and take appropriate preventive and maintenance measures.

Smart Control and Optimization

Sensor technology can also be combined with automated control systems to achieve intelligent control and optimization of production processes. By collecting and analyzing production data in real-time, sensors can adjust production parameters and optimize process flows, enhancing production efficiency and product quality. For example, in smart factories, sensors can monitor the operation of production lines in real-time and adjust the production rhythm and resource allocation according to actual demand, realizing intelligent and adaptive production processes.

Internet of Things and Smart Connectivity

With the continuous development of the Internet of Things (IoT) technology, the application of sensors in smart manufacturing has also become more widespread. By integrating sensors with IoT technology, device interconnectivity and data sharing can be achieved. This improves the transparency and traceability of the production process and provides strong support for the digital transformation of smart manufacturing. For example, IoT-based smart logistics systems, which use RFID technology, can track and locate goods in real-time by reading information from sensor tags, enhancing logistics efficiency and accuracy.

Core Technologies and Future Trends

The ability of sensor technology to achieve these functions is supported by core technologies such as sensor materials, MEMS chips, drivers, and application software. MEMS chips, in particular, are an important carrier for intelligent sensors due to their small size, lightweight, low power consumption, and high reliability. In recent years, with the continuous development of MEMS technology, the performance of intelligent sensors has also significantly improved, providing more reliable and efficient technical support for smart manufacturing.

In the future, sensor technology will continue to develop toward high performance, high reliability, multifunctionality, and intelligence. On one hand, by continuously optimizing sensor materials and MEMS chip performance, the accuracy and stability of sensors will be improved. On the other hand, by introducing advanced technologies like artificial intelligence and big data, sensors¨ intelligence and adaptability will be enhanced. This will provide more comprehensive and robust technical support for smart manufacturing, driving industrial manufacturing to a higher level.

Conclusion: Sensor Technology!The Driving Force of Smart Manufacturing¨s Future

In conclusion, as the cornerstone of smart manufacturing, sensor technology plays a crucial role in data collection and monitoring, fault diagnosis and prediction, smart control and optimization, and IoT and smart connectivity. By continuously optimizing core technologies and developing new sensors, sensor technology will provide more efficient, reliable, and intelligent support for smart manufacturing. In the future, as smart manufacturing continues to evolve, sensor technology will keep playing its essential role, pushing industrial manufacturing toward higher levels. As technology professionals and manufacturing practitioners, we should closely follow the development trends of sensor technology, embrace new technologies and applications, and collectively drive the prosperity and growth of smart manufacturing.