In recent years, there has been a significant increase in the demand for sustainable packaging solutions due to growing environmental concerns and stricter regulations on plastic use. Molded pulp packaging, also known as pulp packaging, pulp molded packaging, or pulp mold packaging, has emerged as a leading eco-friendly option with numerous benefits for the future of sustainable packaging.To get brand praise, dry pressed molded pulp It is necessary to have the spirit of constantly improving the quality of products, but also to have a bunch of eternal heart fire. https://www.pulptray.com/

1. Environmental Benefits of Molded Pulp Packaging

Molded pulp packaging is gaining traction due to its environmental friendliness. Unlike traditional plastic packaging, which can take hundreds of years to decompose, pulp packaging is biodegradable and compostable. Made from recycled paper and cardboard, it helps reduce waste and promotes a circular economy by minimizing the need for virgin resources.

2. Versatility and Durability

One of the key advantages of molded pulp packaging is its versatility. It can be used for a wide range of products, providing excellent protection and cushioning for items such as electronics, consumer goods, food, and beverages. Its shock-absorbing properties make it ideal for fragile items, reducing the risk of damage during transit. Additionally, it can be molded into various shapes and sizes to meet specific product requirements.

3. Cost-Effectiveness

Molded pulp packaging offers cost-effectiveness as the manufacturing process is relatively simple and energy-efficient. This leads to lower production costs compared to other sustainable packaging alternatives. Furthermore, its lightweight nature reduces shipping costs and lowers the overall carbon footprint associated with transportation.

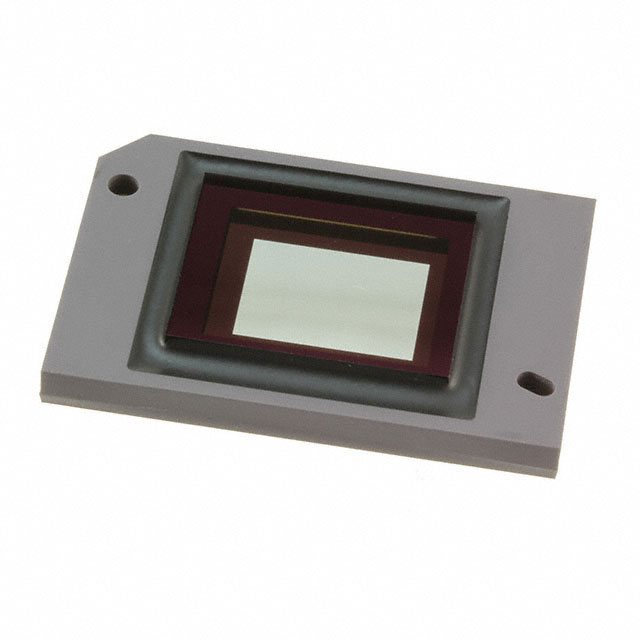

pulp molded tray

pulp mould

4. Consumer Appeal

With consumers increasingly prioritizing sustainability, adopting molded pulp packaging can enhance a company’s brand image and appeal to eco-conscious customers. The natural look and feel of pulp packaging adds a unique, eco-friendly aesthetic that resonates with modern consumers, potentially leading to increased customer loyalty and a competitive edge in the market.

5. Regulatory Compliance

As governments worldwide implement stricter regulations on single-use plastics, molded pulp packaging provides a viable solution to meet these requirements. Being plastic-free, it helps companies avoid potential fines and penalties associated with non-compliance. Additionally, its biodegradability aligns with global efforts to reduce plastic pollution and promote sustainable practices.

6. Innovation and Future Potential

The future of molded pulp packaging looks promising, with ongoing innovations and advancements in technology. Researchers and manufacturers are continuously exploring new ways to enhance the properties of pulp molded packaging, making it even more durable, moisture-resistant, and suitable for a broader range of applications.